From raw material shortages to port congestion, every industry is impacted by global supply chain disruption. Maintaining a competitive advantage in times of unpredictability is a challenge. Let’s investigate how supply chain orchestration helps you to keep promises to your customers and stay ahead of the curve.

Supply chain orchestration is designed to deliver exceptional performance. At its core, a team of experts actively manages your supply chain, end-to-end, using real-time integrated data and predictive analytics to optimise results.

The question is: How can businesses achieve this despite budget constraints, master data struggles and an ever-evolving technology landscape?

The key strategy requires a collaborative network with centralised and accurate data. Yet most companies do not have the expertise or technology to directly connect their systems to all the people they do business with—and do it all in one place.

In a market where customer demands are high and room for error is low, integrated solutions give you a sustainable competitive edge.

Recognizing the challenges

Realizing a digitally coordinated supply chain remains an ambitious goal. Achieving automation and full visibility in real-time is often hampered by poor data quality, inconsistent processes and decentralization of decision-making. Collaboration and compliance suffer when too much customisation is needed between systems, leaving gaps in the analytics required to innovate. Before embarking on a large-scale plan for digital transformation, it is essential to understand these hurdles.

Along with expertise, the success of any supply chain relies on integrated systems that are functional, upgradeable and future-proof. Discovering the possibilities where you can make headway opens the window of opportunity.

Is it “Digitalization vs people” or “Digitalization + people”?

In our digital world, supply chain orchestration works best when technology and human capabilities are combined. While total automation does not yet exist, digitally-assisted solutions do. These operate as transitional paths while full digitalization catches up to our ultimate wish list.

Think of it as the difference between fully autonomous vs driver-assisted vehicles. While the technology is not ready to be fully autonomous without human interaction, advanced driver-assisted systems are becoming standard features on new vehicles. These cars may not drive you to work, but they are smart enough to nudge you over if you drift into the next lane. Likewise, digitally-assisted orchestration helps keep your supply chain in the right lane.

When centralized real-time data is reliable and complete, it can be used to automate repetitive and non-value-adding tasks, comparable to driver-assisted features in vehicles. Collaborators can manage exceptions, forecast and strategize across the supply chain—without delays. Since it is no longer necessary to search for, verify or scrub the data, people have more time to focus on performance-improving activities.

A partnership for success

To achieve successful digital supply chain orchestration, companies must begin with a solid base. Building a data-centric IT architecture is the pivot point for automation and analytics from one consistent source.

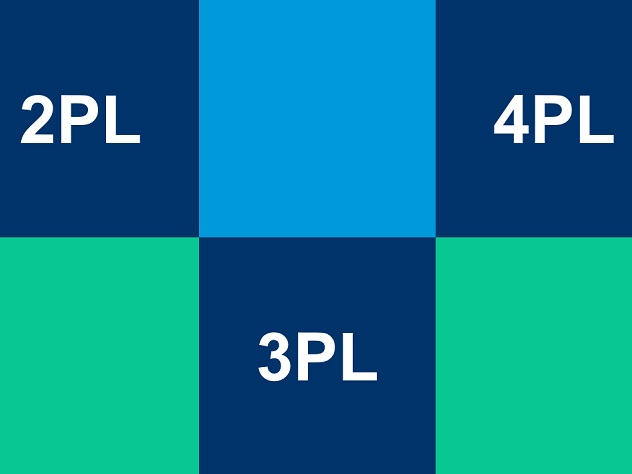

Working with an experienced 4PL partner offers access to innovative technology and a highly vetted network of providers. Position your supply chain for a resilient digital transformation with:

- Collaboration platform connecting all supply chain stakeholders

- Efficient workflows that replace unstructured email communication

- Analytics to identify root causes and causing parties for supply chain deviations

- “Digital workbench”: intuitive interface for exception management and supply chain problem-solving

- Experienced supply chain managers who efficiently address and resolve issues

- A partnership for a sustainable digital path

Your digital future

Kuehne+Nagel Integrated Logistics offers more than 20 years of global 4PL experience to put you on the fast track to supply chain orchestration. Covering all industry verticals and transport modes, our team of professionals use integrated system architecture to provide a seamless digital transition. With worldwide Control Tower locations, proven logistics expertise, and advanced technology, we are well-positioned to transform the most complex supply chains.